Heat pumps offer a sustainable solution for energy efficiency and environmental friendliness. As global demand for HVAC technology grows, innovations in heat exchanger design contribute to improved performance. Let's explore the function, design, and suitability of heat exchangers.

What Is a Heat Exchanger?

A heat exchanger facilitates heat transfer in fluid systems, optimizing thermodynamic processes. Designs vary based on application needs, from traditional to cutting-edge. Widely used in HVAC and refrigeration, heat exchangers excel in temperature control and cost-effectiveness.

How Is Heat Exchanged?

The exchange of heat within a heat pump system follows the principles of thermodynamics. Heat naturally moves from areas of high temperature to those of lower temperature. Rather than generating heat, heat pumps transfer it from a heat source to a heat sink, utilizing the principle of thermodynamics.

Heat transfer occurs through various modes, ensuring efficient processes within the coolant. A heat exchanger, therefore, comprises coils, plates, tubes, and other components working in tandem to facilitate heat transfer. Let's delve deeper:

Conduction: Heat transfer through direct contact between molecules with varying kinetic energy. Heat exchangers utilize walls to facilitate conduction, following Fourier’s Law of Heat Conduction until thermal equilibrium is achieved.

Convection: Heat transfer via the movement of heated molecules along the heat exchanger's wall. As heated molecules rise due to low density, they transfer heat energy to cooler molecules they encounter. This continuous process forms a convection current, governed by Newton’s Law of Cooling.

Thermal Radiation: Emission of electromagnetic energy from a high-temperature surface without requiring a transfer medium. Thermal radiation flows freely, contributing to heat exchange processes.

Flow Configuration of Heat Exchanger

Consider these principles as the pathway of the heat pump refrigerant's movement. Various flow configurations are utilized in the heat exchange process:

Countercurrent Flow

Fluids move in opposite directions within the heat exchanger while maintaining a consistent temperature difference. Highly efficient, countercurrent flow configurations require less surface area compared to concurrent flow.

Cross Flow

Ideal for gas or vapor fluids, this configuration involves liquid passing through tubes while gas flows over the tube's outer surface. Fluid motion is perpendicular, and its efficiency is moderate compared to hybrid and countercurrent configurations.

Hybrid Flow

An innovative blend of multiple heat exchanger configurations, where different flow patterns occur simultaneously. Suitable for applications with constraints like pressure, temperature, and cost.

Types of Heat Exchanger

Indirect Contact Type

Each heat exchanger type includes components serving various functions. Indirect contact heat exchangers feature plates and tubes acting as barriers to prevent fluid mixing during heat exchange.

Typically made of metal, indirect heat exchangers include:

- Plate Heat Exchangers: Thin plates closely joined to enable separate fluid flow, often configured for countercurrent flow with options for modifications like pillow or plate fins.

- Shell and Tube Heat Exchangers: Multiple tubes housed within a larger cylindrical enclosure, allowing for fluid flow inside the tubes and around their outer surface. Compatible with both single and double-phase fluids, they support counter-current or concurrent flow.

Direct Heat Exchanger

In this type, heat transfer occurs through direct contact without separating components. Cost-effective due to fewer components, direct heat exchangers find applications in marine, waste heat systems, and refrigeration.

Purpose of a Heat Exchanger

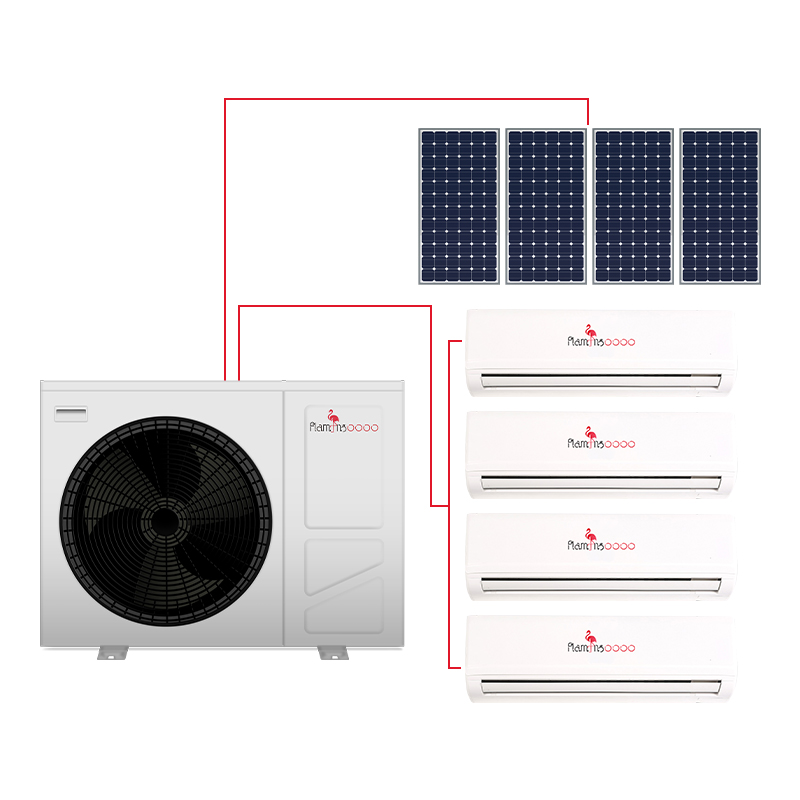

Heat exchanger systems in heat pumps have evolved significantly, focusing on improved designs, temperature distribution, and cost-effectiveness. The primary purpose of this technology is to facilitate the thermal energy cycle within a heat pump, emphasizing design considerations for enhanced energy efficiency.

For instance, the R290 heat pump features a heat exchanger with optimal energy efficiency. Advancements in heat pump technology have enabled the development of heat exchangers with:

Enhanced Materials

Modern heat exchangers utilize materials with superior properties, offering improved durability and efficiency compared to previous models. Innovations in alloy composition and finishing solutions contribute to long-lasting performance, while materials with better thermal conductivity eliminate the need for thickening to resist corrosion.

Enhanced Safety

Newer heat exchanger designs prioritize safety, addressing potential operational issues with features like spring action and floating tubes. These safety enhancements ensure smoother and more secure operation.

3D Printing

The adoption of 3D printing enables engineers to manufacture unique components, allowing for standard AC heat exchanger designs as well as customizations for high-performance heat pumps. This innovation also facilitates the production of smaller and lighter heat exchanger components.

Artificial Intelligence (AI)

AI integration enables heat exchanger manufacturers to optimize performance prediction and manufacturing processes. By leveraging AI for performance issue prediction and resolution, manufacturing parameters are streamlined, resulting in faster and more efficient production.

Nano Fluids

Engineers explore the integration of nanomaterials in heat exchanger designs to maximize efficiency. This innovation is expected to enhance heat exchange processes, leading to more compact designs with reduced weight and improved heat transfer capabilities. These advancements make them suitable for integration into high-performance heat pumps.

How Heat Exchangers Function

Heat exchangers are specifically designed to enable the transfer of heat between fluid molecules exhibiting different temperatures. These devices are compatible with a diverse range of fluid types categorized as process fluid or utility fluid, commonly including refrigerants used in modern heat pumps. With their versatile functionality, heat exchangers play essential roles in numerous industries, facilitating both heating and cooling processes.

How Heat Exchangers Function in HVAC Systems

In HVAC systems, heat exchangers function by utilizing space to facilitate the transfer of thermal energy. They work by exchanging heat between warm and cool air. However, various issues with heat exchangers can impact the overall operation of the HVAC system.

If a heat exchanger becomes damaged, it can hinder the heat exchange process, leading to compromised comfort levels and air quality within the building.