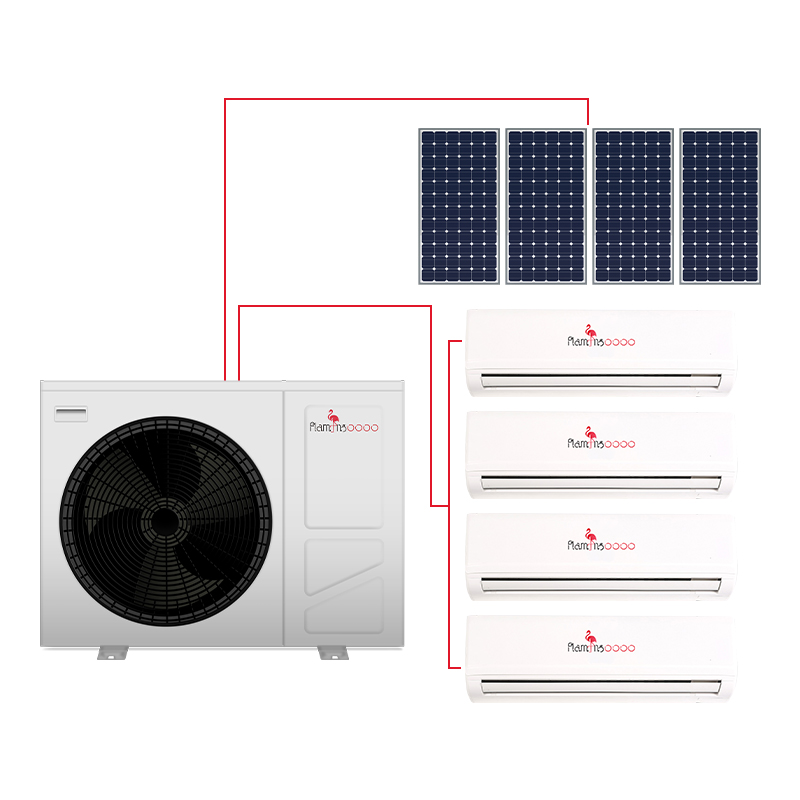

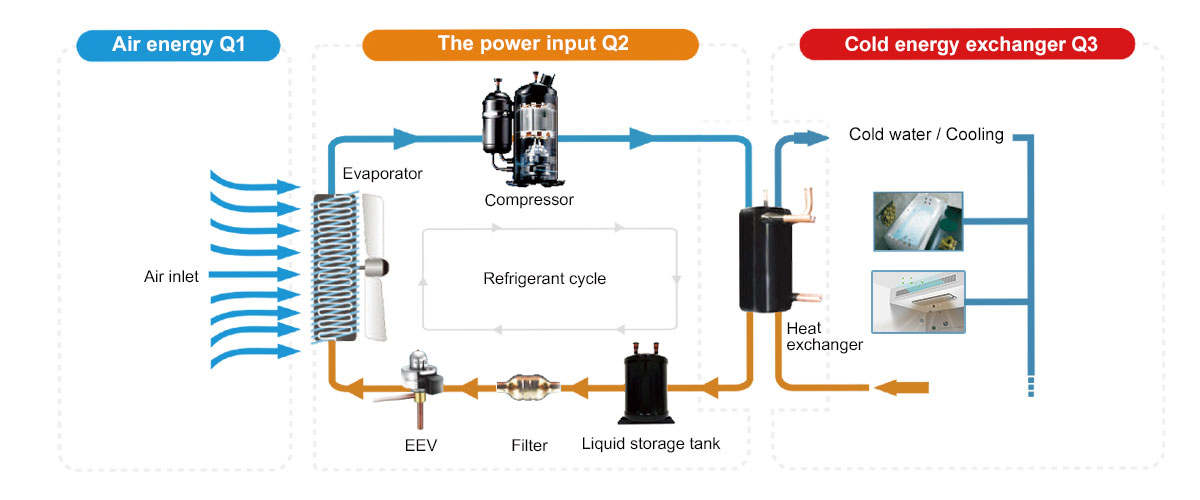

The 2 ton air to water chiller systems is a highly efficient and reliable cooling unit, especially for locations requiring medium cooling capacity. The system utilises advanced air to water chiller technology, which uses air as a cooling source and converts it into a low-temperature water source to meet a wide range of cooling needs.

The use of air to water chiller technology makes the system more energy efficient and lower operating costs. It does not require additional cooling media, but simply utilises ambient air to achieve the cooling effect, which reduces the consumption of energy and resources. At the same time, the technology also reduces pollution to the environment, in line with the modern green concept.

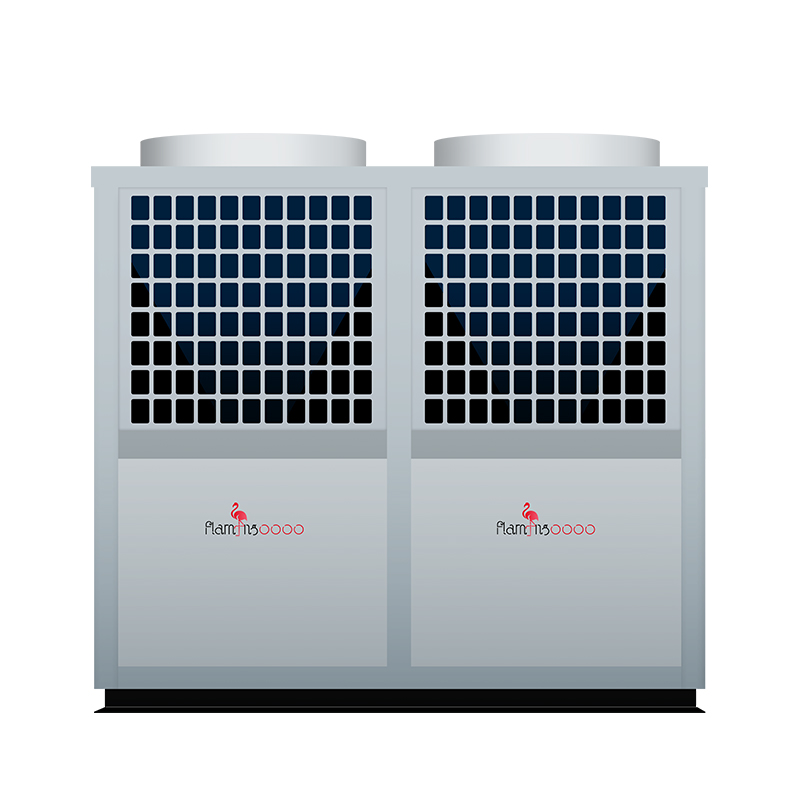

Efficient and stable: Chiller adopts advanced technology and materials, providing efficient and stable cooling effect, able to reach the set temperature quickly and maintain constant temperature.

Energy-saving and environmentally friendly: The chiller has advanced energy efficiency ratio, effectively reducing energy consumption and operating costs. At the same time, the chiller adopts environmentally friendly refrigerants that are harmless to the environment.

Multiple specifications available: The chiller comes in various specifications and models, suitable for different cooling needs and application scenarios. Users can choose the appropriate specification based on actual needs.

Easy to operate and maintain: The chiller design is simple and easy to use, providing convenient operation. Meanwhile, the chiller adopts modular design, making maintenance fast and easy.

Customizable service: Customized chiller services can be provided based on customer-specific needs, meeting special requirements.

Wide cooling range: The chiller's cooling range is wide, adjustable between -10℃ and 30℃, meeting different temperature cooling needs.

Safe and reliable: The chiller adopts multiple safety protection measures to ensure safe and reliable operation, effectively preventing failures and accidents.

Long-lasting design: The chiller uses high-quality materials and craftsmanship, ensuring a long service life.

Low noise design: The chiller has a low noise design, reducing the impact on the surrounding environment.

Intelligent control: The chiller features intelligent control functions, enabling remote monitoring and operation, facilitating user management of the equipment.